How To Use A Torque Multiplier - Norbar Torque Tools

Murtaza Arif

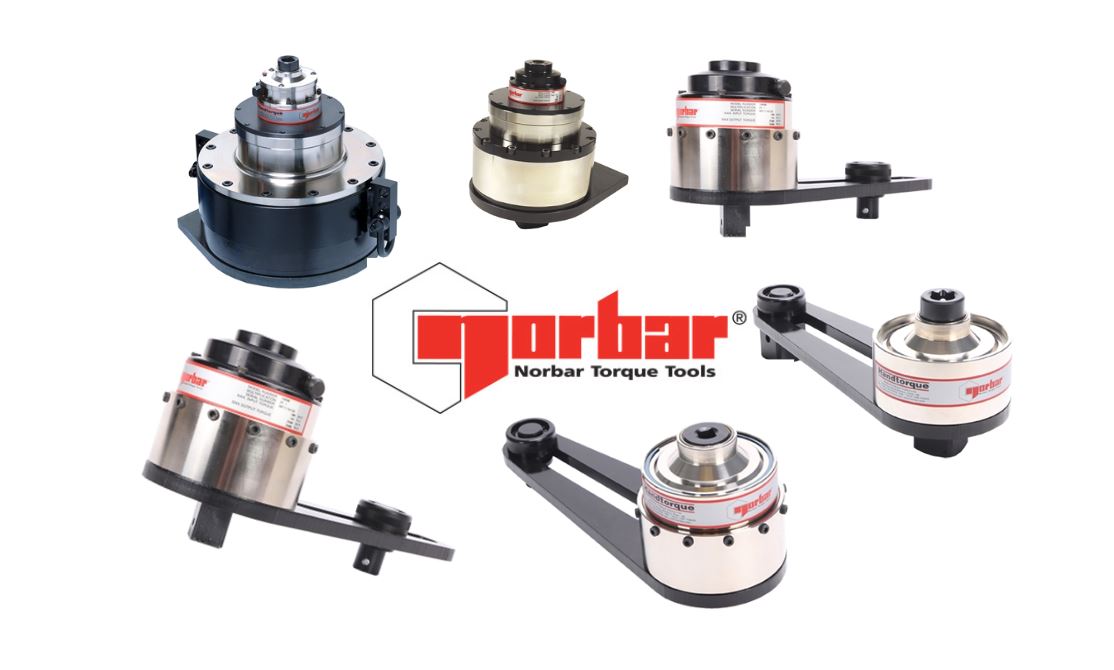

What is a Torque Multiplier?

A torque multiplier is a device that increases the torque that can be applied by an operator. This is because the power output cannot exceed the power input, the number of output revolutions will be lower than the number of input revolutions (Torque x rpm = Power).

How HandTorque® Torque Multipliers Work

HandTorque® multipliers incorporate an ‘epicyclic’ or ‘planetary’ gear train having one or more stages. Each stage of gearing increases the torque applied by a factor of 5, allowing Norbar to offer multipliers typically in ratios of 5:1, 25:1 and 125:1.

In the planetary gear system, torque is applied to the input gear or ‘sun’ gear. Three or four planet gears whose teeth are engaged with the 'sun' gear therefore rotate. The outside casing of the multiplier, or ‘annulus’ is also engaged with the planet gear teeth, and would normally rotate in the opposite direction to the 'sun' gear. A reaction arm prevents the annulus from rotating, and this causes the planet gears to orbit around the 'sun'. The planet gears are held in a ‘planetary’ carrier which also holds the output square drive, therefore as the planet gears orbit around the sun gear, the carrier and so the square drive turns. Without the reaction arm to keep the annulus stationary, the output square will not apply torque

Why use a HandTorque® Multiplier?

• Safety – use of long levers can be dangerous. Torque multipliers allow for a reduction in the lever length or operator effort by a factor of 5, 25 or 125

• Space limitation – the use of a long lever may be impossible due to the available space

• Accuracy – torque will be applied most accurately when it is applied smoothly and slowly. Torque multipliers enable this by removing much of the physical effort from the tightening task

Without Torque Multiplier

With Torque Multiplier

Do’s & Don’ts

Do

-

Read all instructions before use. Incorrect use of multiplier can damage both tools without proper use

-

Maintain the tool according to the advice provided

-

Refer to manual or specifications in order to obtain the required torque

-

Set torque wrench to 1/25th of required torque

-

Check the multiplier is rotating in required direction

-

Choose a suitable reaction point

Check out more Norbar Handtorques

More Info - Click Here

source: norbar.com

Don’t

-

Exceed the Maximum input torque

-

Use Extra-Long extension or socket

-

Use Universal Joints

-

Strike the Anti-Wind Up Ratchet